Wood Synergy Inc. Case Study Analysis

For the identification of the SC bottleneck, the SCOR model should be used

SCOR model is anorganization tool that is used to address, expand, and interconnectstream chain administrationchoices within a firm and with its suppliers and clients.

Pros:

- It builds connections between SC process elements, and metrics through best practices.

- It improves data accuracy, demand forecast, and flow of information.

- SCOR model also improves performance and productivity.

Cons:

- SCOR is a systematic process that may take more time to produce results.

- Not all suppliers and customers like to follow a systematic approach.

- Professional expertise requires to manage the SCOR model at the workplace.

Assimilation of web-based IT tools and SCOR Model implementation in Supply Chain

This is a perfect option that aligns with WoodSynergy’s strategy of cost savings, meeting high demand ensuring optimum quality. The pros and cons are listed below:

Pros

- The collaboration of IT tools and Network Strategy with SCOR will improve productivity and performance.

- This will optimize cost and quality.

- It will strengthen strategic relationships b/w local and international suppliers.

- It will promote IT with innovation in SC.

Cons

- May require additional costs for training and expertise.

- Contracting costs will be high

- Management may resist due to budget constraints.

- Delay in getting contract approval from a strategic partner.

Shift from Remediation to Network Strategy

Part II – Assimilate web-based IT tools with the SCOR Model implementation in Supply Chain Process

Recommendation(s)

The analysis of the alternatives shows a change from a Remediation Strategy to a Network

Strategy gradually would allow the company to ensure. It will eliminate the role of middlemen and their commission and develop a strategic relationship with suppliers, customers, and distributors. With a Network strategy, Wood Synergy can only engage with qualified suppliers who will ensure high-quality, on-time delivery and meet order demands throughout the year. My second part of the recommendation is to ‘Integrate web-based IT tool in Supply Chain with SCOR method to link performance metrics, processes, best practices, and people into a unified structure. The Collaboration of both approaches will improve the strategic relationship with suppliers, and customers, enhance performance and streamline management reporting and internal controls. Both parts of the recommendations are perfectly aligned with WoodSynergy’s goal of achieving growth by meeting the high demand of orders without compromising optimum quality and lead time.

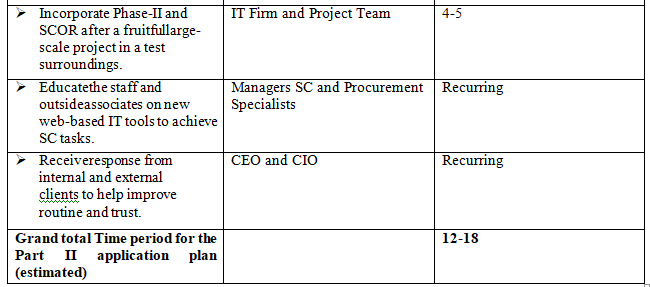

Implementation

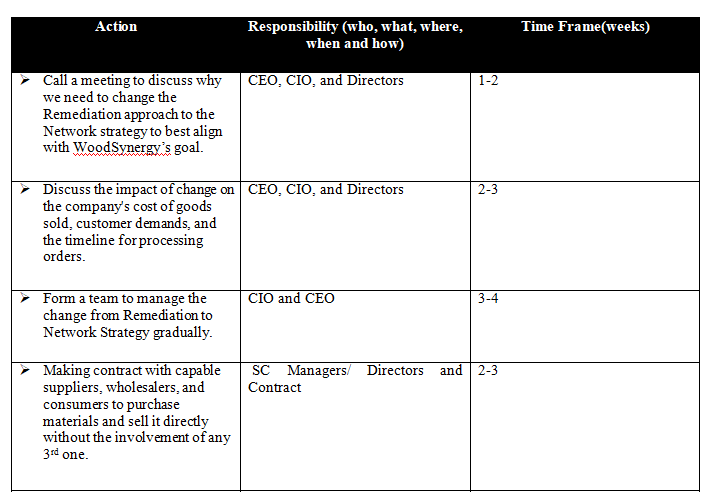

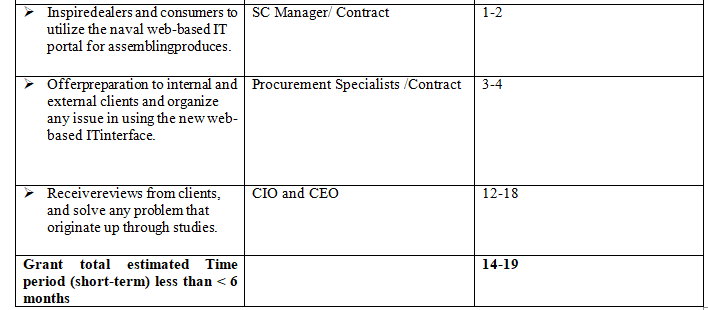

For the implementation of the strategies Call a meeting is required to discuss why we need to change the Remediation approach to the Network strategy to best align with WoodSynergy’s goal. Discuss the impact of change on the company's cost of goods sold, customer demands, and the timeline for processing orders. Form a team to manage the change from Remediation to Network Strategy gradually. Purchase material directly from qualified suppliers, distributors, and customers without involving any third parties. Inspire dealers and clients to assimilate the novel-fangled web-based IT platform for ordering commodities. Then after one to two weeks deliver preparation to core and consumers and assimilate any difficulties in utilizing the new-fangled Information Technology web-based interface. However, to ensure integration is successful, the technical review needs to be completed by Project Team's technical staff. Lead monthly meetings with IT and Project to ensure technical compliance and resolve any software or technical issues (Hall, 2010).

Monitoring and controlling

To guaranteeactual implementation of the above mentioned recommendations, the following KPIs should be used:

An overview of key performance indicators

- Cycle Time: The cycle time for dispensing orders was clearly reduced

- Inventory Turns: Systems progress would result in a high ratio of inventory incomings to inventory turns

- Cost: The elimination of the middleman's commission results in a decrease in cost

- Reject the Ratio: SCOR and IT integration in SC would decrease rejection ratios

- Effectiveness: As a result of improved productivity and performance, profitability ratios would increase

- of orders: Customers' orders will increase as a result of optimized cost and quality

- Sales: Dealing directly with suppliers, distributors, and c ustomers trigger more sales

- Support Tickets: Would decrease due to the effective integration of the IT & SCOR model

- Market Rating: Due to positive feedback from customers, the market rating would be high

- Morale: Employees' morale will be high as a result of improved processes.

Phase 1– Project close-out meeting Metrics:

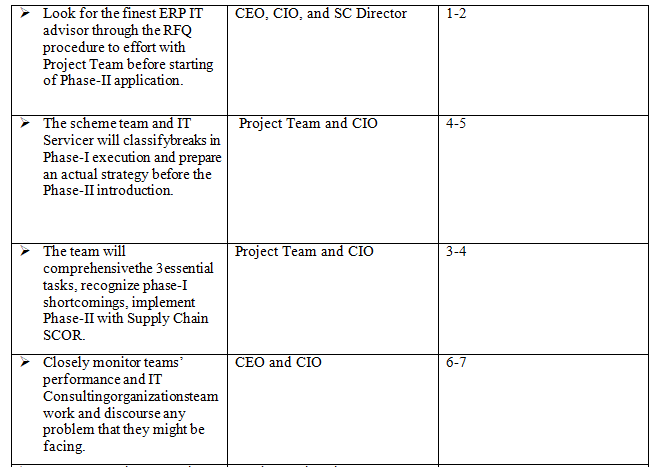

CEO will call a project close-out meeting to find out the ‘lesson learned’ from Phase-I. The meeting agenda should include, what went wrong in Phase-I. Why project planning was not done effectively, and what can we do to prevent these shortcomings in Phase II?

Performance Review Meeting – Bi-weekly, the CEO and CIO will review Phase-I and II progress to identify any challenges and gaps. The project team will be notified about issues that need to be fixed at the post-completion stage of Phase-I and the implementation stage of Phase II.

Phase 2 – Monitoring & Control Stage

Technical Review

To ensure integration is successful, the technical review needs to be completed by Project Team's technical staff. Lead monthly meetings with IT and Project to ensure technical compliance and resolve any software or technical issues.

Quality Compliance

Monthly meetings to monitor the quality & performance of the new web-based ERP tool. Establish a strategy to resolve any issues.

ESAT

Conduct an Employee satisfaction survey to get honest feedback about the new IT-based supply chain processes and address issues that are brought up by employees.........................

Wood Synergy Inc. Case Study Analysis

case solution."}" data-sheets-userformat="{"2":513,"3":{"1":0},"12":0}">This is just a sample partial case solution. Please place the order on the website to order your own originally done case solution.