- Stage 3: Provide Credible Support to the Business Strategy: “Internally Supportive”

To provide credible support to Copeland, Diggs started to invest in its manufacturing process to make it consistent with the business strategy (Focus, Differentiation and Cost leadership). For that, he separated all his services by focusing on cost leadership process and opened the sites Hartselle, Rushville and Shelby to standardize their products across models, rebuild and remanufacturing and large cope focused respectively. These strategies were not only formulated by Diggs but also implemented by him with the help of Dean Ruwe, Dick Peltier and Wes Grenville.

- Stage 4: Pursue a Manufacturing base Competitive Advantage: “Externally Supportive”

To pursue the manufacturing based competitive advantage, Copeland had devised the new type of valve that was 15% more energy efficient than other cost-effective Compressors. By using this valve and making its usage to turn into an opportunity to upgrade their entire line of product to avoid the high failure rates, have been successful and help a lot to avoid the high failure rates.

Copeland Learning from Hartselle, Rushville and Shelby Experiences:

- Learning from Hartselle:

After experiencing the learning from Hartselle, Diggs says that; before Hartselle’s opening, our plants were just making the stuff but after that we realized that manufacturing process could be a new weapon that we could use to get the competitive edge over competitors. After experiencing Hartselle, Copeland got focused on their product by combining the manufacturing process and all of its facilities in one single product line, which had an opportunity for Copeland to endure the competitive advantage over competitors.

- Learning form Rushville:

After experiencing the learning from Rushville, remanufacturing and rebuilding had now became the part of the operations although other after market services remained in marketing. That happened due to the shift in technology which led to the regrouping. Copeland learned that how remanufacturing relied upon the sophisticated production and quality controls methods.

- Learning from Shelby:

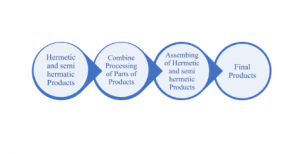

After experiencing Shelby, they learnt that making the different wider distribution dimensions led to get more variability among parts. Before Shelby, all of their products were manufactured and assembled in Sidney where due to the low involvement over semi hermetic compressors and requirement of high horsepower’s was much more likely to fail their products after the introduction in markets due to the huge involvement of costs and high damage ratio (loss) of semi hermetic product during manufacturing time.

Decision Diagram for focus on Sidney Plant:

Decision should be taken for Sidney plant either to split Sidney plant by Copelawelds and Copelametics (two product line) or to split between two process Machining and Assembling.

For splitting Sidney between two product lines requires the reorganization of the plant, separation of employees and their benefits, separation of machinery, separation of duties as well and needs to build the wall for separation of two products to make the two departments of each products. This seems to be very complicated while process split requires the regrouping of equipment so that Copelametics machining will be next to Copelametics assembly.

After analyzing both options, process split is looking cost saving and effective for Sidney plant for Copelametics and Copelawelds products.

Roles and their Impact on Evolution of Copeland’s Manufacturing Strategy:

- Matt Diggs:

Matt Diggs was appointed as the President and Chief Executive Officer of Copeland in 1969. He had the major role in the evolution of the Copeland’s manufacturing strategy. In 1973s, he saw the energy crises as an opportunity to differentiate their product from competitors. In 1975, after retirement of Carl Moeller’s, he standardized all the major components across models to reduce number of parts in products along with reduction of number of models through standardization. He initiated the idea to make separate locations to make these standardization products in Hartselle. The world class remanufacturing plant was envisioned by Diggs in 1972, which was opened in Rushville in 1976. After Hartselle and Rushville, Diggs moved towards the remaining products in Sidney and started thinking over in it. These triggering nature factors led to the opening of the Shelby in 1979. After all that inventions, he was a great President and Chief Executive Officer of Copeland who made the Copeland one of the largest corporations in the world with the implementation of best business strategies; Focus, Differentiation and Cost leadership.

- Dean Ruwe:

Dean Ruwe was hired in January, 1981 as the Vice President of Operations, he spent his early months on job trying after he found the process very frustrating. So, in 1981 Ruwe orchestrated an educational process based on skinner’s work on manufacturing the strategies and produced the four strategic goals for Sidney; a quantum improvement in Copelametics quality, a quantum improvement in Copelawelds costs, a quantum improvement in systems and simplifications of certain design specifications.

- Dick Peltier:

Richard Dick Peltier was hired in April 1978 by Diggs as a Plant Manager. He simplified the process of machining and assembling, lowered the cost through reengineering these processes and making the assemblers jobs simpler to work on final products.

- Wes Grenville:

In 1980 Copeland hired the new plant manager, Wesley (Wes) Grenville. He was hired to manage people and to stabilize labor situations in workplace. After experiencing the work there, Wes started working on machinery and quality control and considered this as his prime task. Few weeks later he started working for changes in machine shop that could be made without the large capital investments and achieved the success by developing the Focused Factory Concept.............

This is just a sample partical work. Please place the order on the website to get your own originally done case solution.