Rangers Creek: Brewing And Distilling Case Study Solution

Flow-rate and Capacity Analysis

Flow Rate Analysis

Flow rate for manufacturing process of the Ranger Creek include the number of gallons or cases produced per unit time i.e. hour. The flow rate analysis can be conducted for the Whisky Drilling process and the Beer Brewing process. (Unknown, Courser a, n.d.)

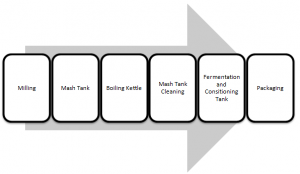

Beer Brewing Process

The flow rate for the Beer Brewing process can be computed by using the time required by each step in the beer brewing process to produce a particular of gallons per batch. A data related to the time required by the each step to produce 930 gallons of beer through the process is given in the Table 1.

Table-1

| Beer Brewing Process Flow Rate Analysis | ||

| Gallons of Beers Produced Per Batch | 930 | |

| Steps | Time Required in hours | |

| Milling | 0.52 | |

| Steep in mash tank | 1 | |

| Transfer to Boiler Kettle from mash tank | 1 | |

| Get the Mix to Boiling Temperature | 1 | |

| Additional Boiling | 1 | |

| Cooling Mixture by Heat Exchanger | 1 | |

| Conditioning Tank | 8 | |

| Filling and Labelling | 8 | |

| Tank Cleaning | 1 | |

| Total Time Required to produce 930 gallons | 22.52 | |

| Flow Rate in hours per gallon | 0.02 | |

It could be seen from the above table that the flow rate for beer brewing process equals to 0.02 hours. It means that the company require 0.02 hours to produce 1 gallon of beer. The flow rate per gallon is highly low which shows that the company is inefficient in managing its operations.

Whisky Drilling Process

The flow rate for Whisky Drilling process can be computed by using the time required by each step in the Whisky Drilling process to produce particular number of cases per batch. A data related to the time required by the each step to produce 100 cases of Bourbon through the process is given in the Table 2.

Table-2

| Whisky Drilling Process Flow Rate Analysis | ||

| Cases of Beers Produced Per Batch | 100 | |

| Steps | Time Required in hours | |

| Distillation 1 | 15.00 | |

| Distillation 2 | 7 | |

| Filling by Gravity Tank | 6 | |

| Set up gravity Tank | 3 | |

| Labelling (Assumed) | 10 | |

| Total Time Required to produce 100 cases | 41.00 | |

| Flow Rate in hours per Case | 0.410 | |

It could be seen from the above table that the flow rate for beer brewing process equals to 0.02 hours. It means that the company require 0.02 hours to produce 1 gallon of beer. The flow rate per gallon is highly low which shows that the company is inefficient in managing its operations.

Capacity Analysis

Capacity Analysis for the Ranger Creek can be conducted using the required capacity, which is assumed to be the sales volume of the Beer and Spirits in the year 2013, and the current capacity of the plant which could be computed by dividing flow rate with the hours per year. It is assumed that the company has 8 working hours per day and operates 365 days in a year. A brief capacity analysis of the beer and spirits is given as follows:

Beer Brewing -628 (3500 barrels)

The required capacity of beer in barrels is considered to be the sales volume in year 2013 that is equals to 3500 barrels of beer. However, it could be seen in the table 3 that the current capacity equals to 2872 barrels showing a net requirement of increasing capacity by 628 barrels annually.

The value 628 is just an estimate as it is computed on the basis of current sales volume. The sales volume could be increased with a higher rate due to increasing demand for company products. Therefore, the management should consider to expand its operations to increase its capacity or to reduce its flow rate in order to optimize its current capacity.

Table-3

| Beer Brewing Capacity Analysis | ||

| Flow Rate in Hours | 0.02 | |

| Total working Hours in a Year | 2920 | |

| Total Capacity in a Year in Gallons | 120604 | |

| Total Capacity in Barrels | 2872 | |

| Required Capacity (Sales Volume 2013) in Barrels | 3500 | |

| Capacity Expansion Required barrels | 628 | |

Whisky Drilling Process 4322 (2800)

The required capacity of whisky in cases is considered to be the sales volume in year 2013 that is equals to 2800 cases. However, it could be seen in the table 4 that the current capacity equals to 7122 showing an excess of capacity by 4322 cases annually.

The value 4322 is just an estimate as it is computed on the basis of current sales volume. The sales volume could be increased with a higher rate due to increasing demand for company products. Therefore, the management should consider to efficiently utilize its current plant to mitigate the growing demand of its products.

Table-4

| Whisky Drilling Capacity Analysis | ||

| Flow Rate in Hours | 0.41 | |

| Total working Hours in a Year | 2920 | |

| Total Capacity in a Year in Cases | 7122 | |

| Required Capacity (Sales Volume 2013) in cases | 2800 | |

| Excess Capacity in cases | 4322 | |

Inventory Analysis

Inventory analysis is required to determine the efficiency of the company to manage its inventory. Inventory management is a vital part of operation management which could substantially increase or decrease the overall profits of the company. If the company has high inventory levels than its demands it would have to bear the holding cost of the inventory, however if the company has low inventory levels than its product demand, it would have to lose its customer's satisfaction. Therefore, an optimal inventory level is require to manage profits and customer satisfaction.

Inventory levels are highly connected with production levels and the existing capacity. In case of Ranger Creek, the company has an excess capacity of whisky drilling cases, which implies that the company would have to control its production levels to avoid over production and the inventory holding cost.

Moreover, Ranger creek has a short capacity for its beer production which implies that the company could face low production levels and dissatisfaction of its consumers in near future. Therefore, in this case the company should manage its production capacity in order to gain optimal level of inventory.

Recommendations

With the deep analysis of company's beer brewing process and whisky drilling process, along with a flow rate and capacity analysis, and an inventory analysis, the company is recommended to extend its capacity by modification in the current plant, as the low capacity is due to the high flow rate which can be reduced by time management.

The company should replace its conditioning tank which takes much time to separate sediment and beer, with a plate filter which would cost $8000 to the company but would allow the time efficiency and reduce the flow rate. Along with it, the company should automatize its filling process in order to reduce wastage of time and high manpower requirement for its filling process. Along with it, the company should purchase an automatic tank washing machine to avoid the huge time and manpower required for washing mash tanks.

Although, modification of the plant would increase the cost related to maintenance and labour, but it would allow the company to meet the required capacity with increasing product demands.

Conclusion

Although, the company remained quite profitable in its first three years of operations, but the current capacity of its plant and the high flow rates of beer and whisky drilling process does not meet the growing demands of the company products. Therefore, in order to conduct its growth plan, the company should first consider to increase its current capacity. In order to do that, the company should modify its current plant, as the modification could be conducted in low time and would enable the company to increase its capacity timely. Although, the modification would increase the operational costs in terms of maintenance and labour, along with it, it would require an initial investment, but the investment and the costs incurred can be covered through the increase in sales and profit margins.

Appendices

Appendix-1: Beer Brewing Process

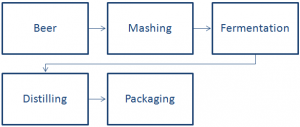

Appendix-2: Whisky Drilling Process

This is just a sample partical work. Please place the order on the website to get your own originally done case solution.