Morgan Components Case Study Solution

Cost reduction techniques

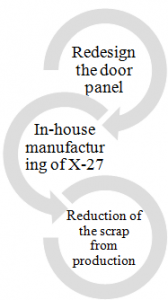

There are various method that can be used by the company to reduce the cost of manufacturing units, the cost reduction techniques are discussed below;

Cost reduction technique 01:

One of the significant method of reducing the cost is to redesign the door panel and make less features in the door panel.

By redesigning the door panel and making less features in the door panel would allow the company to reduce the cost, also the reduction in features and design would also enable the company to achieve the economies of scale benefit over competitors, hence resulted in low fixed cost.

In addition to this, with the less complicated design and reduced features, the company would easily manufacture more volume of door panels and sell to other market players with the condition of completion of project and fewer unit sold.

Cost reduction technique 02:

Another cost reduction technique is the in-house manufacturing of X-27.It is noteworthy that the production of X-27 would most likely require heavy initial cost. Afterwards, it would also require further cost to operate while such technique would bypass the supplier which in turn would result in reduced supplier relations.

In addition to this, the company would have to spend a time and money to gains specific experience and learning in the manufacturing of X-27.

Cost reduction technique 03:

Last but not the least, the reduction and removal of the scrap from production would lead to low production cost. This would be feasible for the company due to the fact that it would allow the company to reduce the moderate portion of cost, hence resulting in reduction in overall cost which in turn would allow the company to lower the final prices of the door panel.

Recommended cost reduction technique

After taking into consideration the evaluation of the various cost reduction techniques, it is to recommend that the most feasible and appropriate technique to reduce the cost would be the combination of removal of scrap from the production and re-designing door panel. The company need to follow the low scrap and less featured door panels which in turn would result in low cost of production.

It is recommended that Sean should go with the project with whatever mean possible. This decision would be supported by the criterion of the relationship of Sean with the Clondalkin Plant. It is to notify that he has strong reputation with Clondalkin. Also, Sean should comvince the executive of Morgan Components who knows that he has strong tie to Clondalkin, which reflects that he might be getting biased. So, Sean should support his argument with the data and facts which would compel them to not to cancel the contract as it would bring the undesirable and unfavorable outcomes.

At time, when the company is extensily striving to minimize the huge financial losses, cancelling contract with Asiacar would put both future and current businesses of the company at stake. In addition, the capacity of Clondalkin Plant would be increased from 60 percent to 90 percent due to the Asiacar contract.

It is analyzed that the target price should be more than 79.2 euros, because at this price, there would be a 0 profit, and to gain profit the price should be higher than this, hence the recommended range of price should between 79.2 and 81 euros.

Conclusion

Conclusively, Morgan Components is one of the most reputed and largest manufacturers and sellers of the automobile parts and components. The company has been engaged in manufacturing the wide range of automobile parts and components which includes Air-conditioning components, chassis, exterior components, electronic components, engine components, and interior components. The Clondalkin plant of the company has been invited to tender for the contract to produce and co-design the front door panels for the new automobile model that is estimated to be launched in 2005. It is to recommend that the most feasible and appropriate technique to reduce the cost would be the combination of removal of scrap from the production and re-designing door panel.The target price should be more than 79.2 euros, because at this price, there would be a 0 profit, and to gain profit the price should be higher than this, hence the recommended range of price should between 79.2 and 81 euros.

Exhibit A – Cost reduction techniques

Exhibit B – Suggested Price Range

| Units | 300000 | |

| Variable cost | 66 | 19800000 |

| Fixed cost | 13.2 | 3960000 |

| Total cost/unit | 79.2 | 23760000 |

| Contribution margin | 13.2 | |

| Profit | 24300000 | |

| Price range | 79.2-81 |

This is just a sample partical work. Please place the order on the website to get your own originally done case solution.