HP Company: DeskJet Printer Supply Chain Case Study Solution

HP DeskJet supply chain

It is imperative to note that the supply chain of HP comprised a network of the distribution centers, manufacturing sites, suppliers, customers and dealers. The HP supply chain has been strengthening the market leading position of company on continuous basis in personal system and printing system, which in turn helping the company to better deliver for the customers on the day to day basis. The company’ supply chain is significant for its customers since the way it interact and communicate with customers and taking, updating and delivering orders drives the customer satisfaction to greater extent.

In addition to this, the effectiveness of the HP’ supply chain can be measured via two key stages in the manufacturing process namely Final Assembly and Test (FAT) and Printed Circuit Assembly and Test (PCAT). FAT is to verify that the components and a system itself function properly, it assemble the sub assemblies such as key pads, cables, motors, skins gears, plastic chassis and the printed circuit assemblies so that the workable printer is produced. In contrast, the Printed Circuit Assembly and Test (PCAT) involves the testing and assembly of the variouselectronic components. The company source components required for FAT and PCAT from external suppliers and other HP divisions. Due to these manufacturing stages, the one week is the average factory cycle time. Also, the transportation is about 24 hours from Vancouver to the US DC and from Vancouver to Europe and east DC is 4 to 5 weeks.

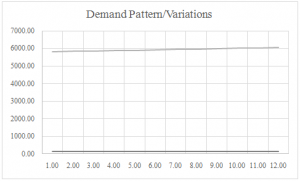

The company has also introduced just in time (JIT) strategy which is based on the historical demand or sales forecast. This strategy is reliant on make-to-stock and target inventory level which is achieved by adding the safety stock and forecasted sales. Furthermore, there are three major sources of uncertainty which are highly affecting the HP supply chain including;

- Incoming material delivery (wrong part, late shipment)

- Internal process (machine down times, equipment efficiency)

- Demand

The demand has impact on inventory and incoming material delivery and internal process has impact on manufacturing lead time.

Solutions Based On Customization or Localization

One of the solutions is the use of air transportation to ship the products to Europe. The company tends to sell the DeskJet in Europe which needs customizing the printer so that it would meet the language of the local countries& power supply requirements. It is important for the company to focus on the localization at the DC in order to reduce the cost at the manufacturing site and it should proceed with the localization of DeskJet printer in the DC. This in turn would allow the company to reduce the shipping cost and put major emphasizes on the local needs in each of its DCs. Additionally, the localization would improve the level of inventory and it would cost the company in terms of decreased holding cost and unchanged shipping cost, inefficient performance with Europe DC (causing time, human capital and extra process).

Conclusion

To sum up, it is to conclude that HP Company was founded in 1939, which manufactures peripherals and computer products. It introduced Deskjet printers in 1988. In early 1980s Canon and HP pioneered the inkjet technology. The manufacturing cycle time have reduced from 8-12 weeks to 1 week and average inventory reduced from 3.5 months ti 0.9 month. The Final Assembly and Test (FAT) and Printed Circuit Assembly and Test (PCAT) are two stages in the manufacturing process.A company source components required for FAT and PCAT from external suppliers and other HP divisions. There are three major sources of uncertainty which are highly affecting the HP supply chain including; Incoming material delivery (wrong part, late shipment), Internal process (machine down times, equipment efficiency) and Demand.

In addition to this, the company had to minimizing the inventory, improve the forecast accuracy and reduce the uncertainty caused by the incoming material delivery, provide the high level of service and determine the right inventory level (best safety stock amount).It is important for the company to focus on the localization at the DC in order to reduce the cost at the manufacturing site and it should proceed with the localization of DeskJet printer in the DC. The localization would improve the level of inventory and it would cost the company in terms of decreased holding cost and unchanged shipping cost, inefficient performance with Europe DC (causing time, human capital and extra process).