Decoding the DNA of the Toyota Case Study Solution

Making Improvement:

Problem identification is the first step in improving any process. As people are expected to make effective changes consistently. Toyota is explicitly involved in teaching people on how to bring improvement by not expecting them to learn in a strict experience. Making of improvement is readily associated with rule 4 which is specifically on how to improve process or services. This stipulates that improving activities of production to connection among machines or workers or the pathways are required to be according to scientific methods under the teacher’s guidance and the lowest possible level of the organization.

Therefore, assistance was provided by consultants to employees and supervisors working in factory in order to bring reduction in lead time of manufacturing. In contradiction, it had been indicated that the structure of organization of companies other than Toyota who followed the Toyota Production System to adapt the nature and frequency were expected to encounter problems.

Countermeasures:

Toyota did not considered the use of specific tools and practices as the standard way to solve any issue like and on cords and Kanban. Rather, these practices had been used by Toyota as a temporary solution to their specific issues. Therefore, such practices or tools were referred to as countermeasure which are as follows:

- Unpredictable yield or downtime:used when any person or machine is not capable to respond against a demand for which safety stock is used.

- Time consuming setups:Suppliers produce products in larger batch sizes due to the difficulties faced by them in switching of machines.

- Consumer demand volume and Volatility mix:Due to the variation in the consumers’ demand,buffer stock is therefore used as a countermeasure.

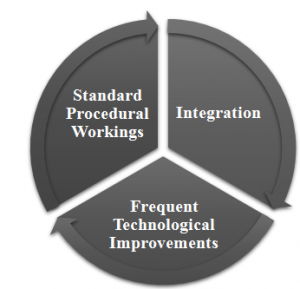

Desirable Characteristics of supply chain:

With the analysis of eth effective manufacturing practices at Toyota, certain characteristics of the desirable work at the factory could be traced. Following are some characteristics, which the companies must acquire in order to get desirable work at their factories:

Standard Procedural Workings

In order to get a desirable work, on the basis of the analysis of the effective manufacturing at Toyota, a company should incorporate standard procedural working at the factory or at the production plant. Standard procedural workings require the companies to introduce certain procedures including detailed steps for performing a task and the time required to complete the step and the task as a whole. Along with it, it requires the companies to make these procedures standard which means that the procedures should not change frequently. The standard procedural working provides efficiency in the business operations.

Integration

Integration is also another way to get the desirable work done at the factory. Integration requires the connectivity within the organization. The employees and the business as a whole must be integrated in a way that provide higher time efficiency. According to the business model used in Toyota, employees should be connected with the top management by their integration with a number of low level managers. Although, complex integration creates confusion in the organization, but, it provides higher time efficiency to the employees in getting their work done if it is managed well.

Frequent Technological Improvements

Moreover, continuous technological improvements in the production plant and in other areas i.e. accounting and inventory management, provides desirable work at the factory. Technological innovations allow the companies to gain operational efficiency and simplify their operations. These innovations allow the companies to reduce the total labor costs at their factory. Moreover, technological improvements enables the companies to change with the dynamic external environment.

Fixation of Production System:

To maximize the productivity, each organization requires an effective plan of production. It acts like a road map, and effective planning depends on a sound comprehension of key exercises that business visionaries and business administrators ought to apply to the arranging procedure.

Forecast expectations of market:

To design viably, you should gauge potential deals with some dependability. Most organizations don't have firm numbers on future deals. As it considers, you can estimate deals depending on authentic data, advertise patterns and additionally settled requests.

Control of Inventory:

Reliable stock levels nourishing the pipeline must be set up and a sound stock framework ought to be set up.

HR and equipment availability:

Also known as open time, this is the time frame permitted between procedures so all requests flow inside your production line or administration. Planning of production causes to oversee open time, guaranteeing it is as well-used, while being mindful so as not to make delays. Planning ought to boost your operational limit however not surpass it. It's additionally insightful not to get ready for full limit and leave space for the unforeseen needs and changes that may emerge.

Standardized time and steps:

Normally, the most effective intends to decide production steps is to guide forms in the request that they occur and after that fuse the normal time it took to finish the work. Keep in mind that all means don't occur in grouping and that many may happen in the meantime.

Subsequent to finishing a procedure map, you will see to what extent it will take to finish the whole procedure. Where work is rehashed or comparative, it is ideal to institutionalize the work and time included. Record comparative exercises for some time later and use them as a pattern to set up future routings and times. This will accelerate your planning procedure essentially.

During the procedure guide organize, you may distinguish squander. You can utilize operational effectiveness/lean assembling standards to dispense with waste, abbreviate the procedure and improve conveyances and expenses.

Conclusion:

Toyota has been a leading and efficiently performing organization in the manufacturing industry of automotive. Although, there are many competitors who tried to copy the production system of Toyota which was at one hand flexible and reliable whereas on the other hand turned out to be complex and confusing. Some desirable characters to be followed by any organization involves Standard Procedural Workings, Integration and Frequent Technological Improvements which were considered desirable in the growth of organization and in process improvement.

Exhibits

Exhibit – Rules of Toyota Production System.

| Rules | |

| Rule 1 | Work should be highly specified in terms of timing, sequence, content and outcome.

|

| Rule 2 | Direct connection between customer and supplier

|

| Rule 3 | Simple and direct pathway of production

|

| Rule 4 | Improvements in methods with respect to scientific methods.

|

Exhibit – Desirable Characteristics of supply chain:

Exhibit – Countermeasures

This is just a sample partical work. Please place the order on the website to get your own originally done case solution.